RECMINE – Environmental Footprint Reduction through Eco-Friendly Technologies of Mine Tailing Recycling

Project title: ENVIRONMENTAL FOOTPRINT REDUCTION THROUGH ECO-FRIENDLY TECHNOLOGIES OF MINE TAILING RECYCLING (RecMine)

Duration of the project: May 2022 – April 2024

Project code: COFUND-ERAMIN-3-RecMine, contract no. 307

Funder: European Comision, Horizont 2020

Programme Coordinator: Fundação para a Ciência e a Tecnologia (FCT), Portugal

[ Romanian version of Abstract ]

ABSTRACT

The aim of this project is the valorisation of high-volume mineral residues from mining and different industrial residues (such as coal combustion by-products (CCP) and demolition waste (DW)) for the development of (i) new geopolymers with low CO2 footprint, and (ii) advanced refractories, suitable for 3-D printing applications.

This will be done through the development of two innovative processing techniques that will be able to make the mine tailings and the industrial wastes suitable for replacing the concrete based on Ordinary Portland Cement (OPC), reducing the requirements of primary raw materials, the waste generation and landfilling. It will be ensured that the developed materials (the geopolymers and the refractories) match the technical and environmental criteria for its use in steel industry or civil engineering applications and develop appropriate business models to secure profitability and sustainability.

Accordingly, the overall objective of the project is to use wastes from five different European countries (Romania, Bulgaria, Portugal, Turkey and Spain) for the obtaining of new green materials, considering the advantages introduced by 3D printing method. Therefore, it is expected to obtain technological progress in the manufacture of geopolymers and refractories which use mine tailings and industrial wastes (CCP and/or DW) as raw materials, due to the presence of a SME as end-user. Moreover, knowing that the synthesis of the materials with similar characteristics (Ordinary Portland cement-based materials) involves consumption of virgin raw materials (kaolin, limestone, sand, gravel, clays) or high temperatures for curing or calcination, the project aims the improvement of currently developed materials by obtaining ambient cured geopolymers with 100% recycled raw materials and self-flowing refractories (high-temperature ceramics) with low or ultra-low cement content that are suitable for 3D-printing.

PROJECT OBJECTIVES

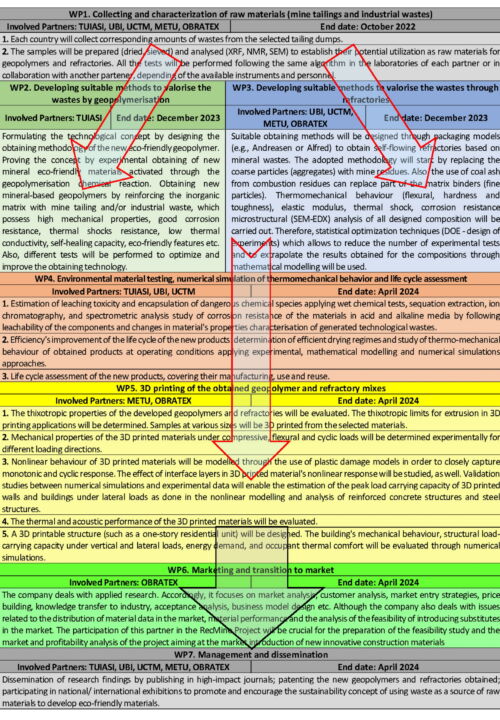

The overall objective of the project (Figure 1) is to utilize wastes from five different European countries (Romania, Portugal, Bulgaria, Turkey and Spain) in order to obtain new green materials, considering the advantages introduced by the 3D printing method.

Figure 1. Project workflow diagram

The main objectives are:

To formulate new technological concepts: to achieve this objective, the eco-friendly technologies of obtaining (i) the new high-performance geopolymers and (ii) the advanced refractories based on mine tailings and/or industrial waste (CCP/DW) will be designed and improved, also, the characterization procedures will be established and the raw materials (mine tailings, CCP and DW) will be collected from different regions of each country.

To propose and demonstrate the obtaining model (obtaining technology): the raw materials will be analysed from the chemical, physical and morpho-structural points of view to establish its identity, purity and quality to ensure the product is suitable for its intended use. Different types of mineral-based geopolymers or refractories will be obtained using appropriate quantities of mine tailings and/or industrial wastes. Establishing a suitable activation method (alkali activation, mechanical activation, or fusion activation) taking into account the characteristics of raw materials. Obtaining geopolymers and refractories based on mine tailings and industrial waste (CCP and DW). Establishing the methods for characterization of the obtained geopolymers.

To validate the eco-friendly technologies in laboratory conditions: this objective will be achieved through advanced material characterization from microstructural (SEM, AFM, NMR and optical micrography), mineralogical (XRD and FTIR), chemical (EDAX, XRF), mechanical (compressive strength, flexural strength, hardness, toughness, elastic modulus and Vicat tests), thermal behaviour (TGA and DTA) and durability (freeze-thaw cycles and leaching) point of view: (i) characterization of the obtained geopolymers and refractories; (ii) optimization of the obtaining methods according to the characterization results; (iii) assessment analysis of environmentally friendly material and (iv) numerical simulation of thermo-mechanical behaviour and life cycle assessment.

To evaluate the geopolymers and refractories for 3D printing applications: this objective will be achieved by 3D printing of geopolymer and refractory mixtures with adequate characteristics: (i) develop a smart 3D printer that can adjust itself according to the thixotropic properties of the developed geopolymers and refractories; (ii) successfully 3D print the selected geopolymers and refractories at various dimensions required for further evaluations; (iii) experimentally determine and computationally model the mechanical properties of the 3D printed materials considering their anisotropy; (iv) experimentally determine thermal and acoustic properties of the 3D printed materials; (v) design a 3D printable structure (such as a one-story residential unit) and computationally evaluate its performance (structural load carrying capacity, energy demand and occupant thermal comfort).

To realize the transition to market of the obtained materials: To achieve this objective, several actions will be carried out: i) Study the building and refractory materials sectors regarding future trends, market volume and the state of the art of 3D printing on them. ii) determine potential customer model companies and sectors, as well as possible competitors in the fields of 3D printing of geopolymers and refractories. iii) Compare developed technology versus conventional technology in terms of time and economic savings to improve market and social acceptance.

EXPECTED RESULTS

[ Romanian version of Expected Results ]

The expected outcomes are to obtain technological progress in the manufacturing of geopolymers and refractories, using mine tailings and industrial wastes (CCP and/or DW) as raw materials. In accordance with subtopic 3.1. “Valorisation of by-products, co-products” and 3.2. “Tailings from mining”, the proposal addresses recycling of waste (mine tailings and CCP/DW) through a low energy consumption method.

Moreover, based on the knowledge that the synthesis of the materials with similar characteristics involves consumption of natural raw materials (kaolin, limestone, sand, gravel, clays – related with OPC-based concrete) or high temperatures for curing or calcination (high energy consumption – related with currently obtained geopolymers) and in accordance with subtopic 2.2. “The use of materials that facilitates reuse”, 2.3. “Use of materials that are recyclable” and 2.4. “Substitution of primary raw materials with secondary raw materials”, the proposal approaches the improvement of currently developed materials by obtaining ambient cured geopolymers with 100% recycled raw materials and self-flowing refractories (high-temperature ceramics) with low or ultra-low cement content with a large amount of mineral residues.

Relevance and expectation: The technologies will serve as a benchmark for research institutions and companies interested in developing a more sustainable environment or those which desire to contribute to the soil decontamination or clearing of dumps area. The obtained materials will become proof-of-concept for further research on the recycling of end-life materials. Local entrepreneurs will improve their understanding of how to collaborate more efficiently with universities to foster their innovation process, products and services.

The project will contribute to the development of competitive technologies to valorise, convert and transform mine tailings and industrial waste (CCP and DW) into raw materials for civil engineering applications. Additionally, the natural raw materials will be preserved, while the CO2 emissions and ecological footprint associated with their exploitation will be significantly reduced.

SCIENTIFIC REPORT – 2022

[ Romanian Version of Report ]

Contract no. 307/2022; stage no. 1/2022;

Reducing the environmental footprint through ecological technologies for recycling mining waste

In stage 1 of the project entitled “Reducing the environmental footprint through ecological technologies for recycling mining waste” which aims to capitalize on large volumes of mineral residues from mining and various industrial residues (such as coal combustion by-products (CCP) and construction waste (DW)) for the development of (i) new geopolymers with a low CO2 footprint and (ii) advanced refractory materials suitable for 3D printing applications, the following activities were carried out: A1. Collection and processing of raw materials (drying, screening, etc.); A2. Chemical, physical and morpho-structural analysis (XRF, EDAX, SEM, XRD) of raw materials; A3. Establishing the methodology for obtaining geopolymers based on mining waste and/or industrial waste (coal ash/construction waste); and A4. Data dissemination, exploitation and management. Risk analysis plan. Promotion of project results in the media (round table, workshops).

The results obtained, in accordance with the activities carried out, led to the realization of the following deliverables:

Deliverable 1: Collection and processing of raw materials (drying, screening, etc.). In order to obtain this deliverable, raw materials suitable for obtaining geopolymers were collected and processed (drying, sieving, etc.) from the following locations:

– Sludge dump owned by ALUM s.a. Tulcea – raw material collected: red mud.

– Thermal power plant ash dumps from S.C. property. VEOLIA ENERGIE IAțI S.A. – collected raw materials: thermal power plant fly ash and lime ash.

Deliverable 2: Bulletins of analysis and characterization of raw materials. In order to obtain this deliverable, the three types of raw materials collected were analyzed chemically (XRF and EDAX), physically (determination of specific density) and morpho-structurally (SEM and XRD) by means of specific methods and equipment.

Deliverable 3: Methodology for obtaining geopolymers. In order to obtain this deliverable, 9 different geopolymer mixtures were designed, consistent with the L9 orthogonal matrix Taguchi method (36). Thus, the methodology for obtaining geopolymers and the main factors that can influence the performance of the studied materials were established.

Deliverable 4: Dissemination of results. Articles published in international journals. Participation in conferences and presentation of the intermediate results of the project. In order to fulfill this deliverable, the brief description of the RecMine project is published online at https://simtit.ro/recmine/. The preliminary results obtained as a result of the activities carried out were disseminated in specialized journals in the following scientific articles: DOI: 10.3390/ma15124178; DOI: 10.3390/coatings12091348; DOI: 10.3390/cryst12091313. Also, the concept of sustainable development promoted by the RecMine project was presented at several conferences and invention salons where it was awarded as follows:

- The Special Prize awarded by the Highly Innovative Unique Foundation (HIUF) at the European Exhibition of Creativity and Innovation (EUROINVENT), May 26-28, Iasi, Romania.

- Certificate of Excellence awarded at The 7th International Invention Innovation Competition in Canada, iCAN, August 27, 2022, Toronto, Canada.

- Diploma of excellence and the gold medal awarded by the Forum of Romanian Inventors Iași at the International Salon of Scientific Research, Innovation and Invention PRO INVENT 2022, October 26-28, 2022, Cluj-Napoca, Romania.

- The Prize of the Faculty of Materials and Environmental Engineering awarded by the “Gheorghe Asachi” Technical University at the International Exhibition of Scientific Research, Innovation and Invention PRO INVENT 2022, October 26-28, 2022, Cluj-Napoca, Romania.

Also, within the project, a Workshop was held on May 27, 2022, which was announced on the http://www.euroinvent.org/conference/program/ page.

In relation to the project implementation plan, all activities and important milestones have been successfully completed by the project team.

SCIENTIFIC REPORT – 2023

[ Romanian Version of Report 2023 ]

Contract no. 307/2022; stage no. 2/2023;

Reducing the environmental footprint through ecological technologies for recycling mining waste

In the second stage entitled “Development of appropriate methods for waste recovery through geopolymerisation. Evaluation of the corrosion resistance of the obtained geopolymers. Management and dissemination.” of the project entitled “Reducing the environmental footprint through environmentally friendly mining waste recycling technologies” which aims at the valorisation of large volumes of mineral mining tailings and various industrial residues (such as coal combustion by-products (CCP) and construction waste (DW)) for the development of (i) new geopolymers with reduced CO2 footprint and (ii) advanced refractory materials suitable for 3D printing applications, the following activities were carried out: A2.1. Obtain batches of geopolymers using appropriate volumes of mining waste and/or industrial waste (coal ash/construction waste). Characterisation of the samples obtained from microstructural (SEM, AFM, NMR and optical micrography), mineralogical (XRD and FTIR), chemical (EDAX and XRF), mechanical (compressive strength, flexural strength, hardness, modulus of elasticity and Vicat tests), thermal behaviour (TGA and DTA) and durability points of view; A2.2. Optimisation of the obtaining methods according to the results obtained; A2.3. Determination of the corrosion resistance of the obtained geopolymers; A2.4. Mobility (participation in conferences and exhibitions). Dissemination, exploitation and data management. Analysis of identified risks. Promotion of project results in the media (round table, workshops).

The activities carried out in stage 2 which are in line with the project objectives resulted in the following deliverables:

Deliverable 1: Obtain batches of geopolymers from different types of raw materials. This deliverable was met by designing and obtaining 9 types of geopolymers for each partner involved in the project. Thus, 45 blends were established, obtained and tested in order to identify the blend with optimal characteristics.

Deliverable 2: Analysis/report of the physical characteristics (morpho-structural and mineralogical) of the obtained geopolymers. In order to fulfil this deliverable, the obtained geopolymers were analysed for each project partner by means of optical and electron microscopy and XRD or FTIR analysis.

Deliverable 3: Analysis bulletins of the chemical characteristics of the obtained geopolymers. The obtained geopolymers were chemically analysed by XRF and EDS in order to study the main chemical elements in their composition and their chemical homogeneity.

Deliverable 4: Analysis bulletins on the mechanical characteristics of the geopolymers obtained. In order to fulfil this deliverable, the 45 types of geopolymers obtained (9 different mixtures of geopolymers for each partner involved in the project, according to the Taguchi method with orthogonal matrix L9) were analysed in terms of compressive strength, flexural strength, hardness as well as through setting time tests. Following the tests, the optimal mix suitable for obtaining precast by conventional methods or 3D printing was determined.

Deliverable 5: Critical analysis and evaluation of the thermal behaviour of the obtained geopolymers. This deliverable was fulfilled by studying the thermal behaviour in terms of phase stability (by DTA tests) as well as in terms of mass evolution (by TGA tests) in the temperature range 22-600 °C. The tests were carried out on the geopolymers with the best and worst mechanical performance specific to each partner involved in the project.

Deliverable 6: Comparative study of the obtained geopolymers. The 9 types of geopolymers obtained with raw materials from each country involved in the project were comparatively analysed in order to determine the optimal blend for obtaining 3D printed precast or by conventional methods.

Deliverable 7: Analysis bulletins on the corrosion behaviour of geopolymers under different environmental conditions. In order to fulfil this deliverable different types of materials have been delivered to the BG partner in order to evaluate their corrosion behaviour.

Deliverable 8: Dissemination of results. Articles published in international journals. Participation in conferences and presentation of project results. Submission of a patent application on the methodology. In order to fulfil this deliverable, a brief description of the RecMine project is published online at https://simtit.ro/recmine/; a patent application is under preparation and part of the results have been published in the following scientific articles/books: DOI: 10.1201/9781003390190; DOI: 10.1007/978-3-031-45964-1_15; DOI: 10.1201/9781003390190-1; DOI: 10.1201/9781003390190-2.

The concept of sustainable development promoted by the RecMine project has also been presented at several conferences and invention fairs where it has been awarded as follows:

– Special Prize awarded by the Highly Innovative Unique Foundation (HIUF) at the European Exhibition of Creativity and Innovation (EUROINVENT), 26-28 May, Iasi, Romania.

– Certificate of Excellence awarded at The 7th International Invention Innovation Competition in Canada, iCAN, 27 August 2022, Toronto, Canada.

– Diploma of excellence and gold medal awarded by the Romanian Inventors Forum Iasi at the International Exhibition of Scientific Research, Innovation and Invention PRO INVENT 2022, 26-28 October 2022, Cluj-Napoca, Romania.

Two workshops were also held in the framework of the project on 04-08 July in Ankara, Turkey (organised by the partner TR-METU) and on 09-11 October in Pamplona, Spain (organised by the partner SP-TEX).

In relation to the project implementation plan, all activities and milestones, which were due to be completed before the submission of this report, were successfully achieved/fulfilled by the project team.

SCIENTIFIC REPORT – 2024

[ Romanian Version of Report 2024 ]

Contract no. 307/2022; stage no. 3/2024;

Reducing the environmental footprint through ecological technologies for recycling mining waste

In the 3rd stage, the determination of the reactivity of the materials was considered, the tests involve placing a solid sample in a plastic cup and adding an appropriate volume of NaOH to obtain a solid/liquid ratio of 1:40. Also, in order to evaluate the dissolution/reactivity process, a part of the solution is tested at different time intervals by means of ICP-OES. Thus the concentrations of Al, Ca, Si and S dissolved during the immersion period are obtained. Based on these data, the alkaline reactivity rate can be calculated as mg of dissolved element per kg of solid sample (mg/kg in the tables). According to the studies, it was observed that by increasing the concentration of NaOH, lower concentrations of Si and Al are obtained in the solution. It is possible that at higher concentrations of NaOH a gel will form and both elements will remain in the solid phase on the filter. In the third stage of the project, the test method was optimized and chemical stability tests were performed on all samples of optimized geopolymers. Thus, testing the chemical stability of the samples was tested through a three-step method that includes: (i) the change of metal ions (bonds with carbonates); (ii) bonds with Fe or Mn oxides; (iii) links with organic matter. At the same time, in order to observe the degree of encapsulation of heavy metals in the structure of geopolymers, stability tests were performed, both on the raw materials used and on the optimized geopolymer samples.

The tests carried out on samples with raw materials from RO reveal the fact that through geopolymerization the total or partial encapsulation of some chemical elements is obtained. At the same time, it can be observed that the encapsulation of heavy metals is closely related to the mechanical characteristics of the developed materials. Figure 6 shows the results obtained for the raw materials used to obtain the S3-RO sample, and Figure 7 shows the specific results of the S7-RO sample, respectively the geopolymers with the best/poorest mechanical performance.

The project contributed significantly to the achievement of the objectives.

To fulfill these, the following activities were carried out: based on the chemical compositions of the waste from all partners, the maximum limits were defined for each of the raw materials; when defining the maximum contents of each of them, the elements fusible at high temperatures and the dimensional distribution of the particles were taken into account, respectively the consideration of mixtures that are easier to process in raw form, i.e. with self-compacting properties.

The main characterizations of the refractory properties were linear shrinkage during sintering (ASTM C179), apparent density, apparent porosity and water absorption (ASTM C24), mechanical 3-point bending strength (ASTM C133) and flow velocity (sonic velocity). , which allowed the dynamic modulus of elasticity to be obtained (BS 1881).

Based on the results obtained, the optimized composition and the most suitable temperature were selected for each of the tested mixtures (MT and CCP) collected in each of the countries (partners) in the consortium.

Corrosion resistance of refractory materials. Corrosion tests were performed on the optimized refractory compositions, namely 5 compositions with a pair of raw materials (MT and CCP/DW) from each of the partners and tabular alumina and reactive alumina. Thus, the samples: REF – Control sample, composed of 100% alumina; RO, with 50% waste, 1400ºC; PT – Portugal, with 30% waste, 1300ºC; BG – Bulgaria, with 30% waste, 1300ºC; SP – Spain, with 30% waste, 1300ºC, TR – Turkey, with 30% waste, 1300ºC, were subjected to contact with a steel cylinder/bar (acidic environment) and a Portland cement bar (alkaline environment) at elevated temperatures (1200ºC) to accelerate the corrosion process. After this first test at 1200ºC, a visual examination was performed and no major changes were recorded. The process was then repeated at a temperature of 1400ºC for the same type of samples. After the two tests, the samples (treated at 1200ºC and 1400ºC) were cut with a diamond disc so that the straight section was exposed under contact with the iron and/or cement. In this way, it is possible to analyze the depth of contamination of the contact elements. These samples were sent to partner P3 for detailed analysis.

For each of the 5 refractory compositions, 13 bricks (prefabricated prototype) were produced, with the actual dimensions: samples of the size of the brick of 0.24×0.115×0.063m. These 65 bricks (prototypes) were sent to partner P5.

In conclusion, the consortium met all the objectives by carrying out the activities provided in the project proposal.

Brief description of the proposed/achieved results of the RecMine project:

| Proposed results | Obtained Results |

| Processed raw materials (dried, sifted). | 24 waste |

| Raw materials analysis and characterization reports. | 15 waste/raw materials |

| Methodology for obtaining several types of geopolymers. | 45 mixes |

| Procedures for investigating the characteristics of geopolymers. | For each type of material |

| Batches of geopolymers with different types of raw materials. | 405 probe |

| Analysis/report of the physical characteristics (morpho-structural and mineralogical) of the obtained geopolymers. | Minimum 10 samples |

| Analysis reports of the chemical characteristics of the obtained geopolymers. | Minimum 10 samples |

| Analysis reports of the mechanical characteristics of the obtained geopolymers. | 405 samples |

| Evaluation reports/analyses of the thermal behavior of the obtained geopolymers. | Minimum 10 samples |

| Comparative study between the obtained values and those already existing in the literature. | Report according tos tage 1 |

| Analysis reports on the estimated corrosion behavior of geopolymers and refractories under various environmental conditions. | For each partner, the sample with the best performances and the one with the lowest performances were analyzed |

| Creative reports. | 2 reports |

| Progress reports | 3 reported to UEFISCDI and 2 to ERAMIN |

| Stage reports | As requested by the funder (4 reports). |

| Results dissemination | 4 Workshops organized by consortium members. |

| Several articles published in international journals. | 1 Article, 1 book, 2 book chapters. |

| Strategic report | Updated throughout the project. |

| Participation in the conference and presentation of the project results. | 6 participations at national/international conferences |

| Awards for participation in exhibitions. | 5 awards or Diploms |

| Two patent applications regarding the obtaining methodology. | 2 patent aplications: A00156/2024 A00170/2024; |

| The final report of the results obtained. | 1 final report |

Project Dissemination

Project Director

Professor PhD.Eng. Petrica VIZUREANU

Phone: +40.744793984

E-mail: peviz2002@yahoo.com